Proper traction is the fundamental condition for propelling a motorized vehicle. Without sufficient road grip, wheels will spin, and the vehicle will not move and it is the same for trucks, buses, coaches, rescue vehicles, fire trucks and passenger cars. However, the consequences of getting stuck without traction and how to correct it is different for each type of vehicle. No matter the vehicle type, if you get stuck with spinning wheels on an icy road, you must increase traction to regain the road grip to continue driving.

It all comes down to friction. When the static friction in the small tire footprint is no longer enough to provide road grip, e.g. on icy roads, kinetic friction will be predominant, and the drive wheel will spin. The wheel will spin until the static frictional force exceeds the kinetic frictional force. This is achieved by either reducing the kinetic friction (throttling down) or increasing the static friction by introducing something with a higher coefficient of friction – a traction aid.

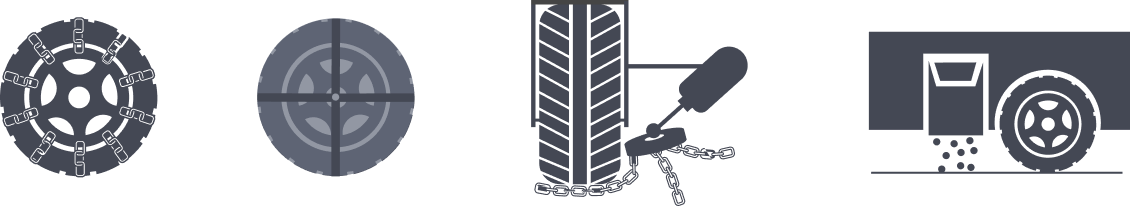

Commonly, traction aids are mechanical tackle introduced between the tire and the slippery road surface to increase friction. Such aids can be anything from textile tire socks to automatic tire chains. Also, sand and mats could be used as a traction aid.

The reasons for tires losing grip are diverse such as a fire truck or ambulance shortcutting over a rain-wet lawn or a truck driving on a muddy forest road. Encountering these summer slippery road conditions may well lead to getting stuck and spinning your wheels. A traction aid could be used whenever you need traction to get the vehicle back rolling. However, for most of us, the risk of skidding and sliding is connected to winter conditions thus this kind of device is synonymous to winter traction aids.

The handling and use of traction aids could be quite different depending on the type of traction aid. For a driver who very rarely encounters icy roads, a sack of sand and a shovel may be a sufficient solution. But, when frequently driving on winter roads, effectiveness and convenient handling are preferable.

Some traction aids are mounted to the tire. Typical traction aids are:

These traction aids must be manually mounted. Once mounted, they stay effective until removed. Depending on their particular design, they are more or less effective. For example, conventional tire chains come in a wide variety of sizes and distinctive designs to fit many tire dimensions and road conditions.

For these aids, there are significant differences in the mounting effort needed. Tire chains for heavy duty trucks are heavy - weighing up to 110 lbs each - and clunky to handle. Consequently, mounting – and subsequent demounting – could be both tiresome and time-consuming.

Contrary to the tire chains, the lightweight and handy textile tire socks are easy and quick to mount, but due to the wearing away by friction of the textile, the strength and effectiveness are reduced as it does not withstand the rough wear for long. Because of this, the textile sock is not a reliable traction aid for longer distances, but could instead be considered as a temporary solution.

If the traction aid is required only for helping the vehicle to start moving, introducing something between the spinning wheel and the slippery ground may be sufficient. Typical emergency aids are:

These are possible solutions to get the vehicle out of a shallow slippery pit, but they will not do for actual driving on icy roads.

Although rare, there are (automatic) solutions where sand is used for increasing traction when driving – at least for limited distances.

Even if the word ‘automatic’ indicates a system works without involvement from the driver, the driver still has to engage the system. This applies to most electronic systems as well as to mechanical traction aid systems.

Note that electronic systems do not increase traction per se, but rather function by preventing tires losing grip by way of an intricate computerized system of wheel rotation speed sensors, controllers, and actuators. Yet to some extent, such electronic systems and 4WD/AWD could be considered traction aids.

Typical traction aids that are engaged from the cab are:

For heavy vehicles like commercial trucks, fire trucks, and buses, not only is road grip vital for safe driving but also delays may have severe consequences. Accordingly, a reliable and effective traction aid is improving both road safety and operative precision.

For transportation trucks operating in winter conditions, a traction aid must be fully effective and reliable after extended use. From a century of experience, steel chains are the aid that at a reasonable price provides proper traction, yet withstands the heavy wear. For most drivers and fleet owners, these advantages outweigh the drawbacks of the heavy, risky, and dirty handling and mounting. That’s most likely why tire chains are the predominant traction aid for trucks and other heavy vehicles.

A combination of sturdy, effective tire chains and convenient instant engagement without manual work would be the optimal traction aid for trucks and other heavy vehicles. This is exactly how automatic tire chains work.

By flipping a switch, chains are introduced in the tire footprint, providing proper traction. The driver doesn’t even have to stop the vehicle for engaging or disengaging the system.

Automatic tire chains provide unparalleled convenience and safety and avoid delays due to slippery road conditions. As such, they are the very best traction aid for trucks, buses, and rescue vehicles.