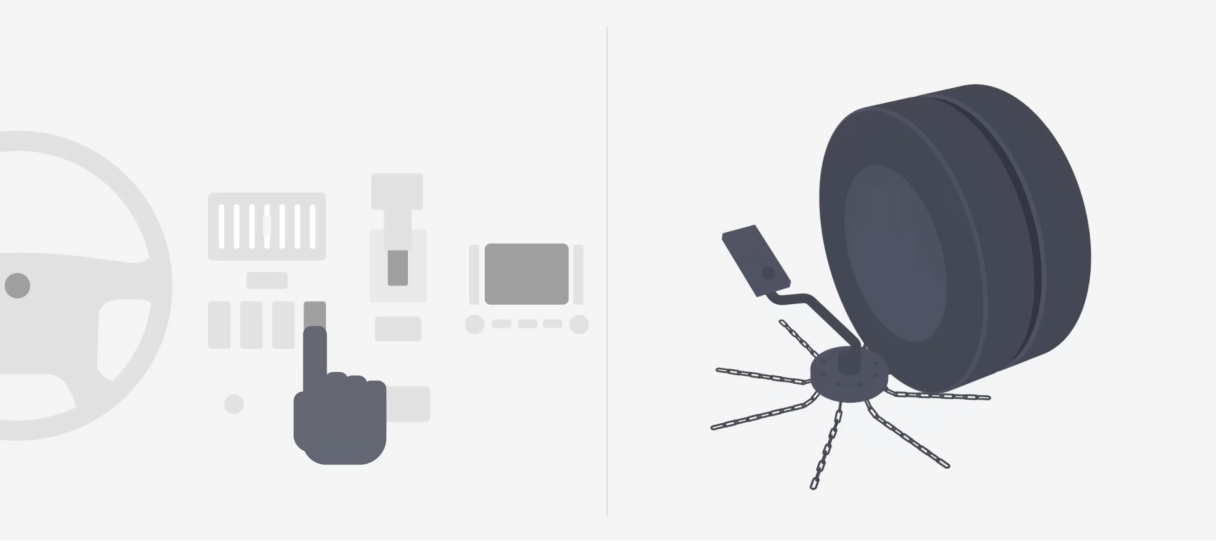

For the uninitiated, it may sound strange that something like tire chains can be automatic at all. To understand the concept, it’s fundamental to know that it is only inside the limited area of the tire footprint that chains – or any other traction aid – are effective. For traditional tire chains, the only way to get chain into the footprint of a rotating wheel is to dress the entire wheel with a net of chains, a work that can be risky, tiresome, and dirty. So, how do automatic tire chains work? Automatic tire chains use a faster, safer, and more convenient method: By flipping a switch, a chain wheel starts rotating and continuously throws chain strands into the footprint. You can read more about its properties here.

Chains are the most effective traction aid. They are durable and withstand heavy wear. However, mounting chains at a roadside can be risky. The passing traffic – often at reduced visibility – is a potential danger. Also, the work is tiresome as chains are heavy, the tires are dirty, and the weather is often very cold at times when chains are needed. And, it takes time to mount! Mounting time varies according to circumstances, but typically it’s half an hour’s work – and the corresponding delay.

With automatic tire chains, just by flipping a switch, you get instant traction and just drive on. You don’t even have to leave the warm cab. Automatic tire chains are the unparalleled way to gain traction as:

Simply, automatic tire chains are the safest and most convenient method to avoid delays caused by slippery road conditions. In this way, they can be regarded as a kind of insurance against various consequences of slippery road conditions.

Not all vehicles can be equipped with automatic tire chains. A certain ground clearance is required to operate the chain wheel swing arms and there simply isn't room enough for the system on a private passenger car. Instead, it’s ideal for trucks, larger vans, and buses.

Commercial transport trucks

Mostly, productivity and profitability in the transportation business are dependent on timely delivery. Irrespective of the cause, delays may have severe consequences on business operations. Also, drivers’ convenience and well-being help to keep up productivity. Automatic tire chains for trucks are a tool for keeping the truck fleet rolling without delays caused by slippery road conditions.

Buses

Whether coaches, school buses, or city transportation buses, passenger safety is imperative. Automatic tire chains improve both road and passenger safety by providing traction in icy road conditions, keeping the bus safely on the road.

For school buses and route buses, timely arrival at stops and destinations are vital. Automatic tire chains for buses are a tool for keeping up with the schedule and arriving on time.

Rescue vehicles

For fire trucks, ambulances, and other vehicles used for rescue operations, arriving in time could be a matter of life or death. In emergencies where every minute counts, unnecessary delays could prove fatal.

Automatic tire chains for fire trucks and ambulances not only prevent rescue operation delays caused by icy roads. Instead, they are an all-year-round traction aid when rescue vehicles need to make their way in muddy parks, over wet lawns or other surfaces where the vehicle tires don’t get sufficient grip.

Despite the many benefits of automatic tire chains, the system has its limitations and precautions must be taken to ensure proper operation.

The cost for installing automatic tire chains is a drawback to some. At the cost of approx. $2,000 per drive axle (for vehicles with air brakes) plus installation cost, it can be considered as an investment in road safety, driver’s safety and well-being, and prevention of costly delays.

Traditional tire chains for trucks come in a vast variety of designs, sizes and chain dimensions. Depending on the vehicles' operation and wheel dimension, there are several factors indicating what type of tire chains would be the optimal choice. However, there is no such thing as one-chain-fits-all-purposes. As operation and driving conditions vary so will the optimal tire chains required.

Automatic tire chains are a completely different story. Unlike traditional tire chains, a vehicle's wheel dimension does not determine the efficacy of automatic tire chains. When engaged, the chains are slung under the tire providing the best possible traction on icy roads making them a reliable traction aid in most slippery road conditions. However, this system does have limitations in deep snow and traditional tire chains designed specifically for deep snow driving may be a better choice. Yet, depending on the consistency of the snow the automatic tire chain system can be effective in deep snow approximately 6 inches or more.

The easy answer is: when winter conditions make the road icy and slippery and you need traction. But, the answer is not that simple. National or regional regulations dictate whether tire chains are permitted or required such as in chain control areas. There are even areas where chains are required in some situations.

Tire chains can cause heavy wear on dry road surfaces and tires thus adding to the cost of road maintenance. They can also have an environmental impact. Due to the heavy mechanical impact on the road surface, particles from asphalt abrasion and tires are released as airborne pollution and swept into waterways.

However, the pros of traveling safely in areas prone to winter road conditions outweighs the cons of road wear albeit with the restriction that the tire chains only be used when snow is present.

The easy answer is: any time you need more traction. As automatic tire chains are engaged just by flipping a switch there is no need to consider whether the improved traction will be worth the mounting time and effort. Also, wear on dry road and tires becomes a non-issue as you just disengage the system as soon as you reach dry road.

Even for interstate or international passage, the automatic tire chains are a non-issue. If you are driving in an area where chains are prohibited, you just don't engage the system.

All methods to increase traction have their pros and cons. Considering different aspects like weight, ease of use, cost, serviceability, reliability, effectiveness etc., no method is the single best option. Rather, different aspects must be weighed together when comparing methods and decide which one best meets your demands.

Even if skipping a traction aid is not really an option there are trucks on the road without any traction aid whatsoever. In areas where icy road conditions are rare, many drivers rely on the heavy vehicle weight increasing static friction. Although illegal in many areas, drivers sometimes lift an axle to increase weight on the drive axle.Sometimes lift an axle to increase weight on the drive axle.

Alternatively, traction aids do make a significant difference by safely increasing traction by introducing a higher coefficient of friction in the tire footprint. Notably, chains are the most effective traction aid.

Tire chains are available in a variety of designs for any truck tire dimension or intended use. Accordingly, they can be optimized for off-road terrain, different snow depths, road surfaces or types of vehicles. Although costly, tire chains are wear-resistant and allow extensive use. Another downside is the tedious mounting and demounting - a tiresome, time-consuming and often risky task which sometimes makes drivers delay mounting / demounting. It is also dirty and heavy work just to regularly unload and stow away the chains.

In comparison, automatic tire chains provide equivalent traction on icy roads but, just by flipping a switch, they are instantly engaged and disengaged with no waste of time or unnecessary wear on tires and road as a result. When not in use, they are conveniently ‘stored’ under the vehicle chassis.

Tire cables are similar to tire chains, but instead of chain links, cables are used to cover the tire. Even though possibly not as effective as chains, tire cables are lighter and known to be easier to mount and demount.

In comparison, automatic tire chains provide arguably better traction with no mounting / demounting work at all.

Tire socks

Textile socks provide good traction on snow – however, less traction on black ice. They are lightweight and easy to stow away. Also, unlike conventional tire chains, they are quickly and easily mounted.

But, they are not wear-resistant and will quickly be worn out if used on dry roads. They are not suitable as the primary traction aid for the truck, but rather an emergency solution.

In comparison, automatic tire chains provide better traction and resist heavy wear. They don’t require mounting as they are engaged/disengaged from the cab – just flip the switch!

Winter tires are designed for better road grip in snowy and icy conditions. As such, they improve safety and maneuverability but, due to physics, rubber tires simply cannot provide enough traction for all driving situations e.g., starting uphill on black ice. Also, winter tires are a costly solution as a set of winter tires for a heavy truck may cost thousands of dollars.

In comparison, automatic tire chains provide better traction and are effective when winter tires as such are not – a fraction of the cost for a full set of heavy truck winter tires.